New rheometer at ANPI

ANPI is specialised in fire prevention. New extinguishing technologies increasingly use foam extinguishers instead of water only. This leads to new verification tests to ensure their performance.

This know-how is intended to be shared with wider applications such as engine lubricants, household liquids, paints, foodstuffs, etc.

1. Rheometer

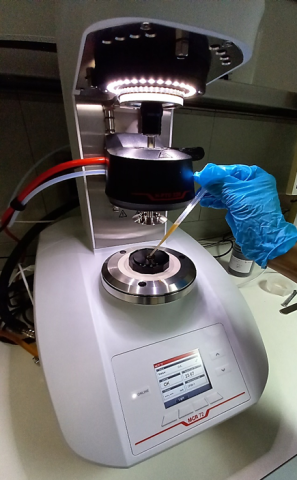

Our ANPI laboratory acquired an Anton Paar rheometer (MCR 72) in 2022 for its platform for characterising the physico-chemical properties of materials.

This instrument allows us to perform viscosity measurements ranging from 10 mPa.s to 50,000 mPa.s and from -35°C to 150°C.

We can perform measurements on fluids and emulsifiers (foams) for quality control or R&D purposes such as oils, liquid soaps, paints, fire extinguishing agents, etc.

2. Viscosity measurement with a rheometer

2.1 Properties

Viscosity is one of the most important properties of a fluid, and is a key factor in determining the flow behaviour of a liquid, emulsifier (foam) or gas.

Viscosity is a measure of a fluid's resistance to flow and can be expressed as dynamic viscosity or kinematic viscosity.

The study of viscosity can help us understand how fluids behave under different conditions, such as temperature, pressure, shear rate and concentration. This knowledge can be used to design better products and processes for various industries such as motor oils or fire-fighting foams.

2.2 Newtonian Viscosity / Pseudoplastic Viscosity

Viscosity is one of the most important physico-chemical parameters to be taken into account when studying the behaviour of fluids (e.g. engine lubricants, fire fighting foams/emulsifiers, etc.).

In all cases, viscosity varies with temperature. Viscosity decreases as temperature increases, and vice versa.

Viscosity can also be a function of fluid speed and shear:

- Newtonian viscosity (sometimes called low viscosity)

- Pseudoplastic viscosity (non-Newtonian) - sometimes called high viscosity

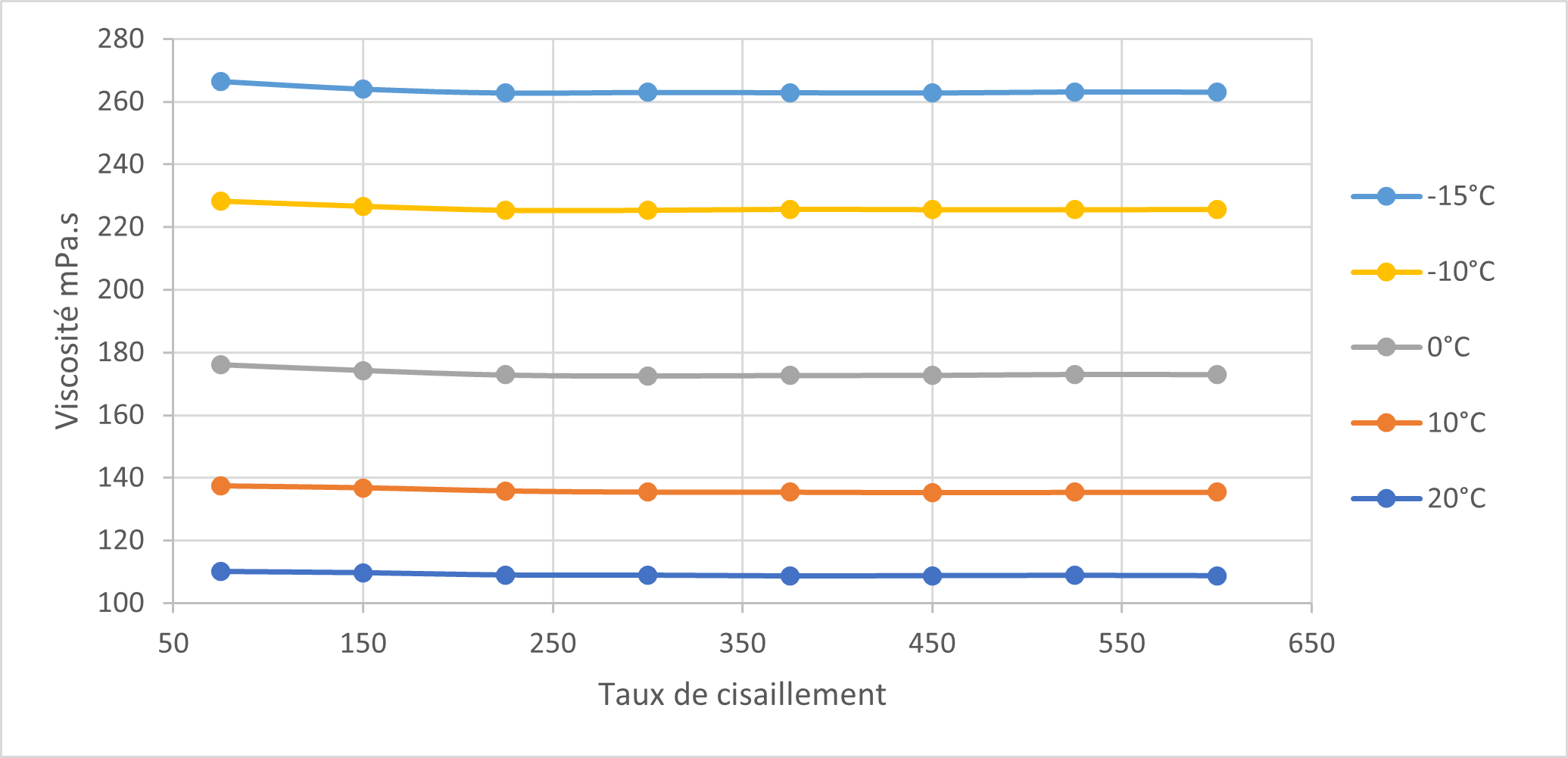

The Newtonian viscosity remains constant regardless of the shear rate (fig. 1).

Figure 1: Newtonian viscosity as a function of temperature (°C)

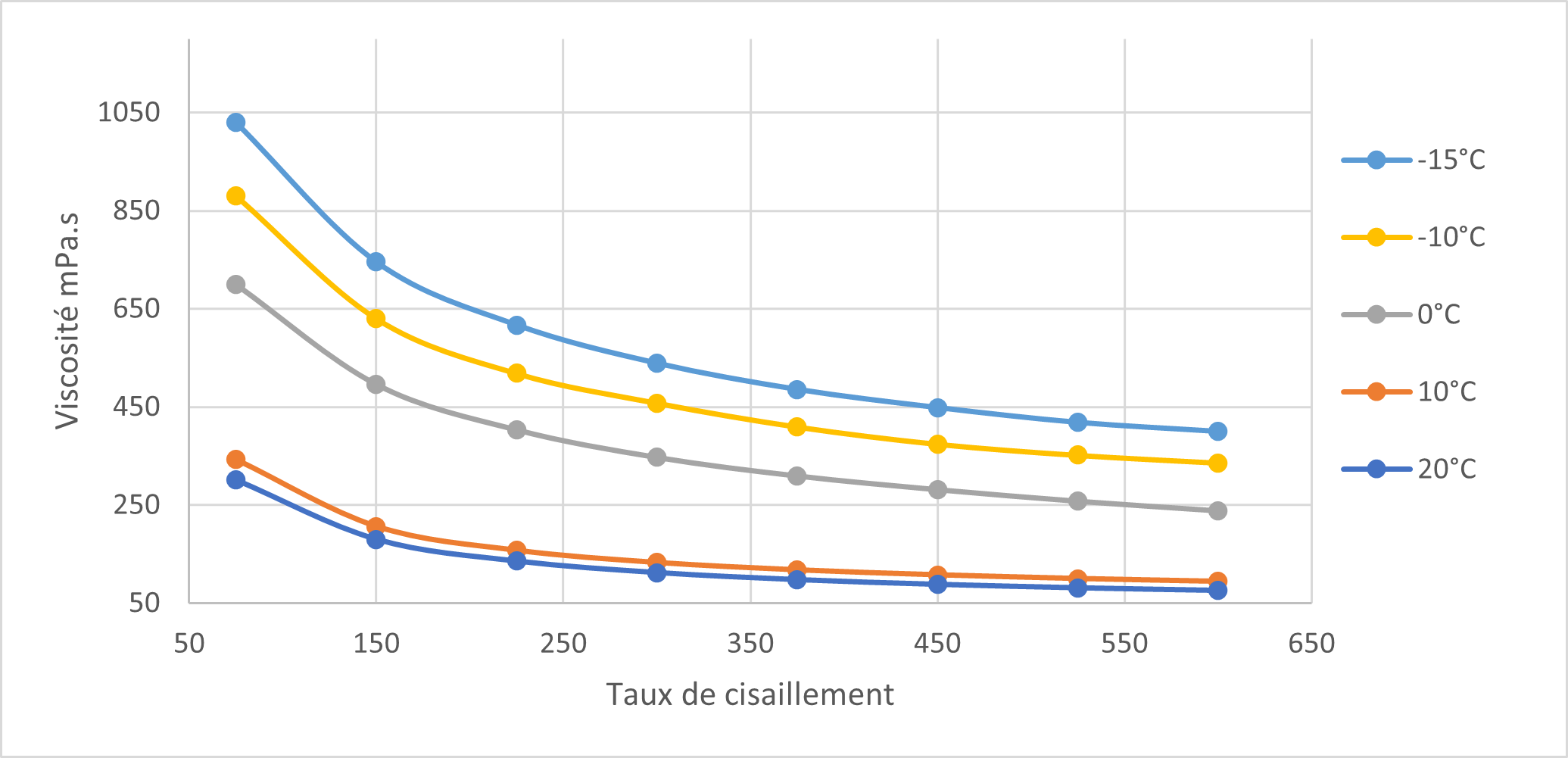

The pseudoplastic viscosity decreases as the shear rate increases (Fig. 2).

Figure 2: Pseudoplastic viscosity as a function of temperature (°C)

Why and when to measure viscosity?

Viscosity must be determined at different stages in the life of a fluid or an emulsifier:

- In the project phase, because it allows the choice of the type of fluid or emulsifier to be oriented, on the one hand according to the application (i.e. type of fire risk in the case of foam extinguishing agents) and on the other hand by taking into account its compatibility with the equipment using this fluid (i.e. a proportioner/mixer allowing the expansion of a foam).

- In the operational phase, because monitoring the behaviour of the fluid or foam over time, particularly in terms of operational and storage conditions, makes it possible to be aware of possible deviations and to remedy them quickly. A fluid or emulsifier that becomes too viscous will have more difficulty moving through the system. Conversely, if it is too low-viscosity, it will move more easily. The risk of incompatibility with the equipment therefore becomes high and can hinder its optimal operation.

Standards and accreditations

Our ANPI laboratory is accredited EN ISO/IEC 17025 by BELAC (certificate number 003-TEST) to perform viscosity tests for ISO 3219 and NBN EN 1568-1/2/3/4. Of course, viscosity measurements outside the accreditation framework can always be performed according to the desired standards.

You would like to receive further information about our test: laboratoires@anpi.be

You would like to receive a quotation: sales@anpi.be